Preparations before calibration

Before you can start the calibration of the weighing instrument,

you should clarify a few things and get prepared.

You should find out the technical characteristics of the

weighing instrument (max weight, d value), the accuracy requirement (max error

allowed and uncertainty) and what to do if the calibration fails (adjustment).

Typically, the whole measurement range is calibrated and the

calibration is performed in the location where the instrument is being used.

Make sure you have enough weights for the calibration procedure available.

The weighing instrument should be switched on at least 30

minutes before the calibration. The temperature of the weights should be

stabilized to the same temperature where the calibration is to be done.

The weighing instrument should be at a horizontal level,

especially for small and accurate weighing instruments. Perform a few pre-tests

by placing weights close to the maximum of the range on the instrument and to

ensure it works normally.

In case the weighing instrument fails in calibration and it is

adjusted, you should make an “as found” calibration before an adjustment and an

“as left” calibration after adjustment.

In the Pharmaceutical industry

calibration of weighing balance is done on a monthly basis to check the accuracy

of the balance. While performing weighing balance calibration check the following

parameters:

·

Accuracy

·

Reproducibility

·

Eccentricity

Accuracy:

Verify the balances for

accuracy with the minimum weight (least count×100 ),5%, 20%, 50% and 90% the capacity of respective balances. Record the displayed weight in respective

monthly calibration formats.

Tolerance:

The variation if any

should be ± least count of the balance for ± 0.2 % of the certified value of the standard weight used whenever is higher and for analytical balance, the

variation should be ± least count of the balance or ± 0.1 % of the certificate

value of standard weight used whenever it is higher.

Reproducibility:

Check the

Reproducibility by using the minimum standard weight of balance capacity.

place the weight in the middle of the weighing pen and observe the displayed

value. repeat the procedure 9 times for the standard weight and record

the reading. Calculate % RSD for both the standard weight by the following

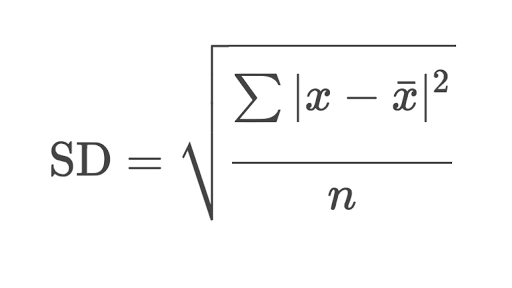

formula.

where x= individual

value

x̄= mean of the

individual value

n= number of values.

RSD= SD*100/ X

Acceptance criteria: %RSD not more than 2.0

%. Record the observations in monthly calibration record as per “monthly calibration

record of weighing balance”.

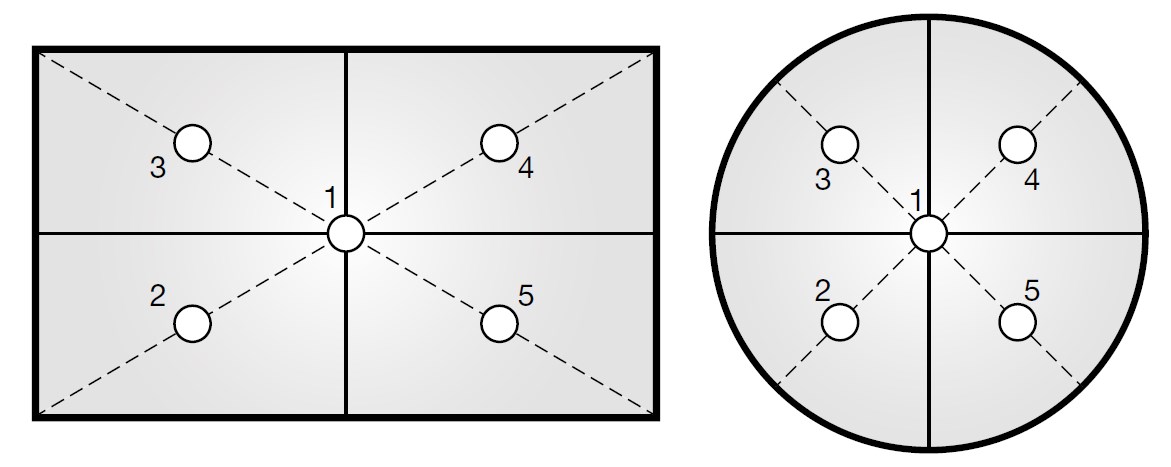

Eccentricity:

Take the minimum weight and

keep at on specified position as shown below calculate %RSD by following the formula is specified above.

Acceptance criteria:

% RSD not more than 2.0

%. Record the details of calibration in labels with Marker Pen. write the

identification number of the standard weight used during verification and

calibration in the designated place of verification and calibration records.

Calibration record shall be verified by

a quality assurance by

putting “reviewed by quality assurance” stamp along with initials and

date. calibration of analytical balance in the quality control department shall

be done as per their respective SOP.

Calibration of balances by external agency:

Internal calibration

(software calibration) of weighing balances shall be done by external agencies.

calibration certificate received from an external agency shall be reviewed

comprising the detail of balance and calibration summary.

Action to be taken if out of

calibration:

If the balance is out

of calibration to refer sop “handling of out of calibration” and rise

deviation as per SOP “handling of deviation” and a fix the label “out of

calibration” as per SOP (status labeling) and inform to Department Head of

Investigation.

Raise maintenance memo

and inform the engineering department for rectification action. if required

take a balance of configuration from another section and department for

carrying out the weighing activity. In Such situations, carry out Daily

verification of transferred balance and used for Weighing. if the parameter of

Daily verification does not meet with the specification, monthly calibration

should be done. Once rectification of the balance is done, calibrate the

balance and record the same in respective calibration records. the balance

shall be released for further use only on satisfactory closure of the deviation

with detail result of Investigation.

Hello Dear..

ReplyDeleteI appreciate your Informative post and It's very helpful.thanks for sharing Keep it up!

Weighing Balance | Testing Instruments | Bursting Strength Tester Digital

Thanks for appreciation!!

ReplyDelete